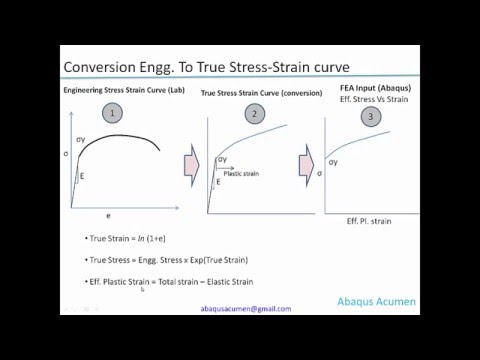

True stress = (engineering stress) * exp(true strain) = (engineering stress) * (1 + engineering strain) where exp(true strain) is 2.71 raised to the power of (true strain).

Q. What is the difference between engineering stress-strain curve and true stress-strain curve?

The curve based on the original cross-section and gauge length is called the engineering stress-strain curve, while the curve based on the instantaneous cross-section area and length is called the true stress-strain curve. Unless stated otherwise, engineering stress-strain is generally used.

Table of Contents

- Q. What is the difference between engineering stress-strain curve and true stress-strain curve?

- Q. Do we measure engineering stress-strain curve or true stress-strain curve in our lab experiments if given a choice which one will you prefer and why?

- Q. What is true strain and engineering strain?

- Q. What is the formula for stress and strain?

- Q. What is the true strain at necking?

- Q. What is the proportional limit on a stress-strain curve?

- Q. What is necking in polymers?

- Q. What is necking in stress-strain curve?

- Q. What causes the yield point to drop in steel?

- Q. What is yield stress of steel?

- Q. Why does mild steel have two yield points?

- Q. In which grade of steel a definite yield point is obtained?

- Q. What is the difference between upper and lower yield strength?

- Q. Which steel does not yield point?

- Q. How do you calculate yield strength of steel?

- Q. Is added to rise the yield point of low carbon steel?

Q. Do we measure engineering stress-strain curve or true stress-strain curve in our lab experiments if given a choice which one will you prefer and why?

Yes, both you can use because till the yield point or elastic limit the engineering stress-strain curve or true stress-strain curve is almost similar i.e. there is almost no variation. It varies after yield point i.e. where the plastic deformation occurs.

Q. What is true strain and engineering strain?

Engineering strain is the amount that a material deforms per unit length in a tensile test. Also known as nominal strain. True strain equals the natural log of the quotient of current length over the original length as given by Eq4.

Q. What is the formula for stress and strain?

stress = (elastic modulus) × strain. As we can see from dimensional analysis of this relation, the elastic modulus has the same physical unit as stress because strain is dimensionless.

Q. What is the true strain at necking?

Necking or localized deformation begins at maximum load, where the increase in stress due to decrease in the cross-sectional area of the specimen becomes greater than the increase in the load-carrying ability of the metal due to strain hardening.

Q. What is the proportional limit on a stress-strain curve?

So, the proportional limit is defined as the highest stress at which the stress-strain curve is a straight line. Below the proportional limit, there is no permanent deformation in a structure, that is, the object returns to its original position after the removal of applied force.

Q. What is necking in polymers?

Necking or cold drawing is a smoothed jump in cross-sectional area of long and thin bars (filaments orfilms) propagating with a constant speed. The necks in polymers, first observed about seventy years ago, arenow commonly used in modern processing of polymer films and fibers.

Q. What is necking in stress-strain curve?

Necking occurs when an instability in the material causes its cross-section to decrease by a greater proportion than the strain hardens when undergoing tensile deformation. Necking behavior is disregarded in calculating engineering stress but is taken into account in determining true stress.

Q. What causes the yield point to drop in steel?

Yield point phenomenon is understood to occur when stress drops down drastically because the locked in dislocations are set free. The dislocations are locked in due to presence of carbon in case of low carbon steels or mild steels.

Q. What is yield stress of steel?

Yield Strength in Steel Yield strength is the maximum stress that can be applied before it begins to change shape permanently. This is an approximation of the elastic limit of the steel. If stress is added to the metal but does not reach the yield point, it will return to its original shape after the stress is removed.

Q. Why does mild steel have two yield points?

The stress-strain curve for certain low carbon steels displays a double yield point. The material is expected to plastically deform at stress δ1. However, small interstitial atoms clustered around the dislocations interfere with slip and raise the yield point to δ2.

Q. In which grade of steel a definite yield point is obtained?

Mild Steel Reinforcement Mild steel bars are also known as Fe 250 because the yield strength of this steel is 250N/mm2. The stress-strain curve for mild steel is given inFig. 1.1. It shows a clear, definite yield point.

Q. What is the difference between upper and lower yield strength?

A few materials start to yield, or flow plastically, at a fairly well-defined stress (upper yield point) that falls rapidly to a lower steady value (lower yield point) as deformation continues. Any increase in the stress beyond the yield point causes greater permanent deformation and eventually fracture.

Q. Which steel does not yield point?

(1) Yield Strength or Yield Limit Medium carbon steel and high carbon steel have no obvious yield points, so 0.2% of the stress of the residual deformation is the yield strength, expressed by σ0.2, shown in Figure 8.2.

Q. How do you calculate yield strength of steel?

The stress-strain diagram for a steel rod is shown and can be described by the equation ε=0.20(1e-06)σ+0.20(1e-12)σ3 where s in kPa. Determine the yield strength assuming a 0.5% offset. 5000=0.20σ+0.20(1e-6)σ3 solving for σ=2810.078kPa.

Q. Is added to rise the yield point of low carbon steel?

Phosphorus is added in low carbon steels to raise it’s yield point. Manganese is added in low carbon steel to.