Q. How is tool face calculated?

The toolface can be found using the following formula:

- – toolface angle, deg.

- – azimuth change, deg;

- The number of wedges (

- is the angle of the blade of the wedge.

- – length of deviation section, m (ft);

- Input data:

- Calculation of dogleg angle.

- The Dogleg of the correction to reach the required direction is 6.7 deg.

Q. What is magnetic tool face?

Magnetic toolface is the angle, or azimuth, of the borehole survey instrument within the wellbore measured clockwise relative to magnetic north and in the plane perpendicular to the wellbore axis; the north, east, south and west directions have magnetic toolface angles of 0°, 90°, 180° and 270°, respectively.

Table of Contents

- Q. How is tool face calculated?

- Q. What is magnetic tool face?

- Q. What is gravity tool face?

- Q. What is Mag gyro Toolface?

- Q. What is high side in directional drilling?

- Q. What is high side Toolface?

- Q. What is high side drilling?

- Q. What do directional drillers make?

- Q. What is the toolface of a drilling rig?

- Q. What does north mean on an oil field toolface?

- Q. How is the orientation of the toolface measured?

- Q. What is the tool face of a steering tool?

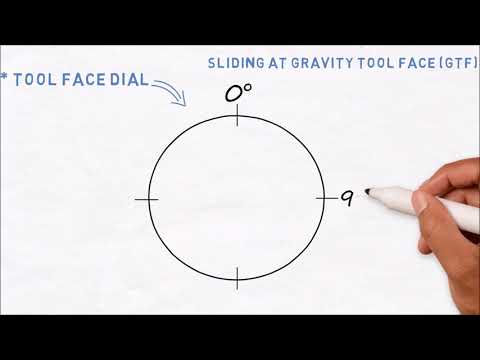

Q. What is gravity tool face?

Gravity toolface is the angle of the borehole survey instrument within the wellbore measured clockwise relative to up and in the plane perpendicular to the wellbore axis; the high side (maximum build), maximum right, low side (maximum drop) and maximum left directions have gravity toolface angles of 0°, 90°, 180° and …

Q. What is Mag gyro Toolface?

The magnetic or gyro toolface is the orientation of the tool face measured on a perpendicular plane. When measured using a magnetic tool, it is called a magnetic toolface and when measured by a gyroscope, it is called a gyro toolface.

Q. What is high side in directional drilling?

The high-side is the top of the hole perpendicular to the wellbore axis and the low side is the bottom of the hole (Figure 2). The tool is measure in relative to high-side tool face.

Q. What is high side Toolface?

High-side toolface is the angle of the borehole survey instrument within the wellbore measured clockwise relative to up and in the plane perpendicular to the wellbore axis; the high side (maximum build), maximum right, low side (maximum drop) and maximum left directions have high-side toolface angles of 0°, 90°, 180° …

Q. What is high side drilling?

Highside Drilling is Australia’s leading horizontal directional drilling (HDD) steering company. Our reputation is based on the success of our projects. We are behind some of the most technical and geographically-challenging projects in Australia, New Zealand and Asia.

Q. What do directional drillers make?

Directional Driller Salary

| Annual Salary | Monthly Pay | |

|---|---|---|

| Top Earners | $70,500 | $5,875 |

| 75th Percentile | $60,000 | $5,000 |

| Average | $55,564 | $4,630 |

| 25th Percentile | $43,000 | $3,583 |

Q. What is the toolface of a drilling rig?

Last Updated on Wed, 06 Jan 2021 | Drilling Engineering The ” Toolface ” of a deflection tool, or a steerable motor system, is the part (usually marked with a scribe line) which is oriented in a particular direction to make a desired deflection within the wellbore. There are two ways of expressing toolface orientation:

Q. What does north mean on an oil field toolface?

1. n. [Drilling] The angle measured in a plane perpendicular to the drillstring axis that is between a reference direction on the drillstring and a fixed reference. For near-vertical wells, north is the fixed reference and the angle is the magnetic toolface.

Q. How is the orientation of the toolface measured?

Toolface orientation is measured and expressed in this way at low inclinations, generally less than 5°. High Side Toolface is the toolface orientation measured from the high side of the borehole in a plane perpendicular to the axis of the hole.

Q. What is the tool face of a steering tool?

Toolface : Magnetic Tool Face (MTF) , Gravity Tool Face (GTF) , Tool Face Orientation. The sensors used in steering tools and MWD/LWD tools are solid-state electronic devices known as magnetometers and accelerometers which respond to the earth’s magnetic field and gravitational field respectively.