Q. How many types of pulping process are there?

According to its refining degree, it can be divided into three kinds: unbleached, semi-bleached and bleached. Unbleached pulp contains a small amount of lignin and colored impurities, so it is yellow and the fiber is hard.

Q. Why is wood bark is not used in the pulp & paper industry?

Only the heartwood and sapwood are useful for making pulp. Bark contains relatively few useful fibers and is removed and used as fuel to provide steam for use in the pulp mill. Most pulping processes require that the wood be chipped and screened to provide uniform sized chips.

Table of Contents

- Q. How many types of pulping process are there?

- Q. Why is wood bark is not used in the pulp & paper industry?

- Q. Which are 4 broad categories of pulping processes?

- Q. What is non wood fibers?

- Q. Which pulping process is the most expensive?

- Q. What are the most common chemicals used in pulping process?

- Q. What is wood pulp primarily used for?

- Q. What tree is used for pulp?

- Q. What is wood pulp used for?

- Q. What is plant pulp?

- Q. What country invented soda pulping?

- Q. How does kraft pulp mill work?

- Q. What’s the percentage of wood pulp in the world?

- Q. What kind of raw materials are used for pulping?

- Q. Why is bamboo pulp so important in China?

- Q. Which is an emerging resource for worldwide pulping and papermaking?

Q. Which are 4 broad categories of pulping processes?

Explanation: Following are the four broad categories of pulping: Chemical, semi-chemical, chemi-mechanical, and mechanical. These are in increasing order of mechanical energy required to separate fibers and decreasing reliance on chemical action. 3.

Q. What is non wood fibers?

Nonwood fibers, also referred to as ”alternate fibers”, are nonwoody cellulosic plant materials from which papermaking fibers can be extracted. The most widely used nonwoods for papermak- ing are straws, sugar cane bagasse, bamboo, kenaf, hemp, jute, sisal, abaca, cotton linters, and reeds.

Q. Which pulping process is the most expensive?

Extended Delignification Chemical pulping and bleaching of chemical pulps are both delignification reactions. Of course, bleaching reactions are much more specific for lignin removal than pulping but are much more expensive.

Q. What are the most common chemicals used in pulping process?

Chemical wood pulping involves the extraction of cellulose from wood by dissolving the lignin that binds the cellulose fibers together. The 4 processes principally used in chemical pulping are kraft, sulfite, neutral sulfite semichemical (NSSC), and soda.

Q. What is wood pulp primarily used for?

Put simply, wood pulp is a lignocellulosic fibrous material that is produced by separating cellulose fibers from wood, fiber crops or waste paper. Unsurprisingly, pulp is regularly used as the source material in paper products. You can find this ingredient in everything from newspapers to toilet paper.

Q. What tree is used for pulp?

Paper is made from softwood or hardwood trees, but 85% of the wood pulp that makes paper in the U.S. comes from softwood coniferous trees. They have longer fibers known to produce stronger paper. The primary trees in this category are pines, firs, spruces, hemlocks, and larch.

Q. What is wood pulp used for?

Wood pulp is a versatile material used for a wide variety of products. “We can consider four main end uses for wood pulp. They are tissue, printing and writing papers, board and specialty papers.

Q. What is plant pulp?

What is Pulp? Pulp is made from breaking down the fibrous part of plants, primarily trees or recycled paper, and refers to the main ingredient in the papermaking process. Pulp made from trees (wood fiber) is the most common source of fiber for papermaking and the base for many paper and wood products.

Q. What country invented soda pulping?

Soda pulping, invented in England by Burgess and Watts in 1851, uses sodium hydroxide as the cooking chemical. Finding little enthusiasm in England for this new process, Burgess brought the method to the United States in 1854, and the first mill was started in 1866.

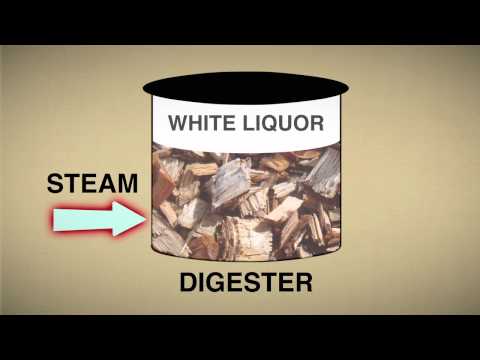

Q. How does kraft pulp mill work?

We make kraft pulp by mixing wood fibres with a solution of caustic soda and sodium sulphide, and cooking them inside a digester. This separates the fibres from the lignin, which is a natural glue-like substance that binds them together.

Q. What’s the percentage of wood pulp in the world?

Nowadays, in the total pulp consumption of the world, the proportions of wood pulp, wastepaper pulp, and non-wood pulp are 63, 34, and 3%, respectively. The bamboo, and bagasse, would play a major role in optimizing papermaking raw materials.

Q. What kind of raw materials are used for pulping?

This kind of raw materials include bamboo, bagasse, rice straw, is generally around 50%, closing to wood. However, with the heterogeneity of cellulose, the utilization of this kind of plant in pulping is far less than that of wood. 2.2. Bast ber materials

Q. Why is bamboo pulp so important in China?

However, due to shortage of wood resources, utilization of non-wood fibers remains important in China. The total production capacity of bamboo pulp in China reached 2,400,000 tons in 2017, and most of the bamboo pulps (about 80%) are for the production of household paper grades.

Q. Which is an emerging resource for worldwide pulping and papermaking?

” Bamboo as an emerging resource for worldwide pulping and papermaking ,” BioRes. 14 (1), 3-5. As a widely distributed and fast growing graminaceous plant, bamboo has emerged as an important raw material for pulping and papermaking to mitigate the shortage of wood resources, at least in the East Asia region.