Factors Determining the Cooling Rate. The four most important factors determining the actual cooling rate are the type of quenching medium, the temperature of the quenching medium, the surface condition of the part and the size and mass of the part.

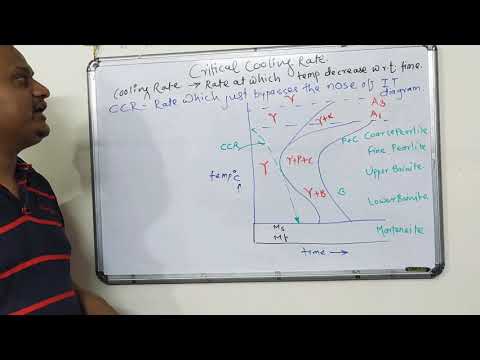

Q. What is the critical cooling rate?

The minimum rate of continuous cooling just sufficient to prevent undesired transformations. For steel, the slowest rate at which it can be cooled from above the upper critical temperature to prevent the decomposition of austenite at any temperature above the Ms. Glossary.

Table of Contents

- Q. What is the critical cooling rate?

- Q. In which medium cooling rate is slow?

- Q. What is critical cooling rate in TTT diagram?

- Q. Why is cooling rate important with quenching?

- Q. How cooling medium is selected for hardening treatment?

- Q. What is the fastest quenching medium?

- Q. What’s the difference between cooling and quenching?

- Q. Why is quenching in oil better than water?

- Q. Why is quenching in water bad?

- Q. What is difference between quenching and annealing?

- Q. Is normalizing cheaper than annealing?

Q. In which medium cooling rate is slow?

Answer. 1. According to the theories the cooling rate is slow in air mediam.

Q. What is critical cooling rate in TTT diagram?

61. Critical Cooling Rate (CCR) If the cooling curve is tangent to the nose of TTT curve, the cooling rate associated with this cooling curve is Critical Cooling Rate (CCR) for this steel. Any cooling rate equal to or faster than CCR will form only martensite.

Q. Why is cooling rate important with quenching?

Surface and Heat Treatment Processes In general, the highest quenching cooling rate can lead to highest hardness and the best combination of strength and toughness, and obtain the good corrosion resistance, so in order to get good mechanical properties and corrosion resistance, high cooling rate might be adopted.

Q. How cooling medium is selected for hardening treatment?

A work piece is hardened by heating it to the specified temperature, then cooling it rapidly by submerging it into a cooling medium. Oil, brine or water may be used. The resulting part will have increased hardness and strength, but the brittleness increases too simultaneously.

Q. What is the fastest quenching medium?

Water is able to quench heated metals rapidly as well. It can cool a metal even faster than oil. One benefit of water is that flammability of the media is not a concern.

Q. What’s the difference between cooling and quenching?

As nouns the difference between cooling and quenching is that cooling is a decrease in temperature while quenching is (physics) the extinction of any of several physical properties.

Q. Why is quenching in oil better than water?

Oil is preferable to the traditional quenching medium of water because it reduces the risks of distortions or cracking by cooling metals more evenly and more quickly.

Q. Why is quenching in water bad?

Water is one of the most efficient quenching media where maximum hardness is desired, but there is a small chance that it may cause distortion and tiny cracking. These oil-based fluids often oxidize and form a sludge during quenching, which consequently lowers the efficiency of the process.

Q. What is difference between quenching and annealing?

During the annealing process, the structure does not change, mainly to eliminate the internal stress of the metal. Compare quenching with annealing and normalizing, the main difference is the quick cooling, the purpose is to obtain martensite.

Q. Is normalizing cheaper than annealing?

Normalizing is also generally less expensive than annealing because it does not require additional furnace time during the cool down process.