Q. What is double housing planer machine?

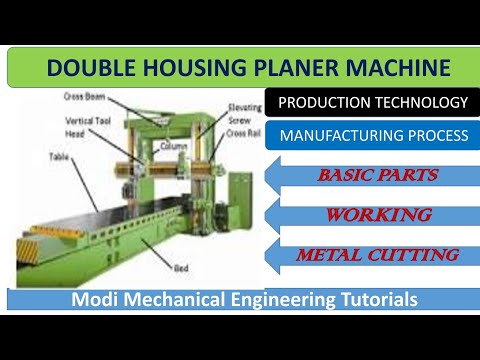

Standard or Double Housing Planer Machine A double housing planer has a long heavy base on which a table reciprocates on accurate guideways. The length of the bed is little over twice the length of the table. Two massive vertical housings or uprights are mounted near the middle of the base, one on each side of the bed.

Q. What is working principle of planer machine?

Working principle of Planer Machine The reciprocating motion of the ram is obtained by a quick return motion mechanism. As the ram reciprocates, the tool cuts the material during its forward stroke. In return stroke, there is no cutting action and this stroke is called the idle stroke.

Table of Contents

- Q. What is double housing planer machine?

- Q. What is working principle of planer machine?

- Q. What is the advantages of planer machine?

- Q. Which of the following planer has two work tables?

- Q. What is planing machine process?

- Q. What is planing in machine?

- Q. How does a planer work?

- Q. What is the difference between shaper and slotter?

- Q. What is open side planer?

- Q. Which machine job reciprocates?

- Q. Which tool is used in planer machine?

- Q. How much can a planer take off?

- Q. What kind of work can a planer machine do?

- Q. How is a planer machine similar to a shaper machine?

- Q. What is the cutting stroke in a planer machine?

- Q. How is the cross rail on a planer machine moved?

Q. What is the advantages of planer machine?

There are some advantages of Planer Machine and those are: Greater accuracy. Good surface finish. The major advantages are at a time more than one tool can perform on the workpiece. Low maintenance requires comparatively other machine tools.

Q. Which of the following planer has two work tables?

Two tables can fix jointly to hold large workpieces. 3. Double Housing Planer Double housing planer is the major type of planer. It consists of mostly a massive bed on which work table respond, and two vertical columns or housing, one on every side of bed.

Q. What is planing machine process?

Planing is a common manufacturing process that involves pressing and rotating a workpiece against a fixed and stationary cutting tool. As the workpiece rotates, the cutting tool removes material from it. It’s called “planing” because the cutting tool produces a plane on the surface of the workpiece.

Q. What is planing in machine?

A planer is a type of metalworking machine tool that uses linear relative motion between the workpiece and a single-point cutting tool to cut the work piece. A planer is similar to a shaper, but larger, and with workpiece moving, whereas in a shaper the cutting tool moves.

Q. How does a planer work?

A planer is used to make a board that’s been jointed flat equal thickness from end-to-end. A flattened board is placed on the planer table (bed) and pushed in. The machine’s feed roller grabs the board and pulls it through and past a rotating cutter headset above the bed, which removes wood.

Q. What is the difference between shaper and slotter?

Slotter Machine Slotting machine is quite identical to Shaper machine. The only difference lies in the cutting mechanism, ie horizontal and vertical. In slotting machine works with holding ram in vertical axis and cutting action in downwards stroke only. Rams are either crank driven or hydraulic driven.

Q. What is open side planer?

: a planer having the crossrail supported by a housing on one side only.

Q. Which machine job reciprocates?

Shaper

Shaper is a reciprocating type of machine tool in which the ram moves the cutting tool backwards and forwards in a straight line. The work-piece is rigidly held in a vice or clamped directly on the table. It is intended primarily to produce flat surfaces.

Q. Which tool is used in planer machine?

Shapers and planers use single-point tools to machine flat surfaces. Shapers move the cutting tool back and forth over the material, peeling away the surface, whereas planers have stationary tools, and the surface is moved to encounter them.

Q. How much can a planer take off?

Examine the width of the lumber. Most planers remove a maximum of 3 mm per pass. If a narrow piece of lumber is being planed, the maximum amount may be removed. A piece that it at the maximum width of the planer may cause the motor to overheat and the cutter to stall.

Q. What kind of work can a planer machine do?

It is capable to make deep cuts and apply heavy feeds to finish the work in a short time. The tool is stationery and work is moving. Multiple tooling permits machining of more than one surface at a time. Tools used are heavier, stronger and larger. Cutting and return speeds are uniform throughout the stroke.

Q. How is a planer machine similar to a shaper machine?

It is similar to the shaper machine but in case of size, the planer machine is larger. The workpiece slots move here from one point to another for operation, whereas in the shaper machine the workpiece slots were in a stationary position.

Q. What is the cutting stroke in a planer machine?

The tool single point cutting tool is fixed in the tool head and the workpiece is fixed on the work table. Now we switch on the machine that means power supply to the machine and the worktable moves forward hence it cuts the material and it is called cutting stroke.

Q. How is the cross rail on a planer machine moved?

The cross rail may be moved up and down on the face of the housing by means of elevating screw and can be clamped at any position and it is parallel to the top surface to the table. The front face of the cross rail provided with accurately machined guideways for cross-feeding the tool head saddle by means of a screw.