Q. What is fed to the Sulphur recovery plant?

An acid gas has the following composition: 40.2 mol% H2S, 54.0 mol% CO2, 1.35 mol% CH4, 0.15 mol% C2H6 and 4.3 mol% water. It is fed to a thermal stage (combustion reactor) of a Claus Process Sulphur Recovery Unit (SRU) at 40 °C, 179 kPa and 5000 kmol/h.

Q. What process is used to recover sulfur?

The Claus process

The Claus process is the most significant gas desulfurizing process, recovering elemental sulfur from gaseous hydrogen sulfide. First patented in 1883 by the chemist Carl Friedrich Claus, the Claus process has become the industry standard.

Table of Contents

- Q. What is fed to the Sulphur recovery plant?

- Q. What process is used to recover sulfur?

- Q. What is the purpose of sulfur recovery unit?

- Q. How does a Sulphur plant work?

- Q. How do you make liquid sulfur fertilizer?

- Q. What catalyst is used in Claus process?

- Q. What is modified Claus process?

- Q. Is Claus process exothermic?

- Q. How do you make liquid sulphur fungicide?

- Q. What does the Claus sulfur recovery process mean?

- Q. How much sulfur is produced in a sulfur recovery plant?

- Q. How much sulfur is in the tailgas from Claus?

- Q. How is hydrogen sulfide produced in the Claus process?

Q. What is the purpose of sulfur recovery unit?

Sulfur Recovery Units (SRU) from Air Liquide Engineering & Construction use a combustion and catalytic process to recover a pure form of sulfur from acid gas streams containing hydrogen sulfide. If credit is given for steam produced in the SRU, operating costs can be negligible.

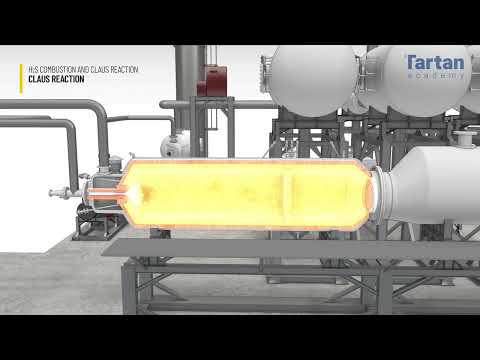

Q. How does a Sulphur plant work?

The sulfur plant converts H2S gas into elemental sulfur that can then be sold as a finished product. The process results in a molten sulfur product that can either be sold directly in liquid form or converted into solid pellets by cooling with water.

Q. How do you make liquid sulfur fertilizer?

Moreover, the liquid sulfur fertilizer is produced through the steps of: producing detoxified sulfur by mixing sulfur, phyllite, loess, caustic soda, bay salt, and water; producing a wetting agent by mixing caustic potash, canola oil, and water; and producing a liquid sulfur fertilizer by mixing the detoxified sulfur …

Q. What catalyst is used in Claus process?

Alumina or bauxite is sometimes used as a catalyst. Because this reaction represents an equilibrium chemical reaction, it is not possible for a Claus plant to convert all the incoming sulfur compounds to elemental sulfur. Therefore, 2 or more stages are used in series to recover the sulfur.

Q. What is modified Claus process?

The Modified Claus Process is one of the most common methods for sulfur recovery from acid gas streams. An extensive survey of the open literature has been carried out to collect rate expression and experimental data for the reactions of the Claus reaction furnace.

Q. Is Claus process exothermic?

We have increased the flowrate of oxygen to increase the conversion rate. We have studies the effect of temperature on the Claus process. When the temperature is increased then the recovery of sulfur is decreased. The Claus reaction is exothermic reaction in which a large amount of heat is released.

Q. How do you make liquid sulphur fungicide?

When using wettable dust, such as Hi-Yield Wettable Dusting Sulfur, mix 4 tablespoons of sulfur in 1 gallon of water, advises Hi-Yield. Once the sulfur spray is thoroughly mixed, pour it into a hand sprayer and spray your plants. Repeat as recommended by the product label.

Q. What does the Claus sulfur recovery process mean?

The Claus Sulfur Recovery Process Sulfur recovery refers to the conversion of hydrogen sulfide (H2S) to elemental sulfur. Hydrogen sulfide is a by-product of processing natural gas and refining high-sulfur crude oils. HYDROGEN SULFIDE (H2S) SYNONYMS: SOUR GAS OR ACID GAS

Q. How much sulfur is produced in a sulfur recovery plant?

The average production rate of a sulfur recovery plant in the U. S. varies from 51 to 203 Mg (56 to 224 tons) per day. Hydrogen sulfide, a byproduct of crude oil and natural gas processing, is recovered and converted to elemental sulfur by the Claus process. Figure 8.13-1 shows a typical Claus sulfur recovery unit.

Q. How much sulfur is in the tailgas from Claus?

Tailgas from the Claus plant still contains 0.8 to 1.5 percent sulfur compounds. Existing new source performance standards limit sulfur emissions from Claus sulfur recovery plants of greater than 20.32 Mg (22.40 ton) per day capacity to 0.025 percent by volume (250 parts per million volume [ppmv]).

Q. How is hydrogen sulfide produced in the Claus process?

Hydrogen sulfide is a by-product of processing natural gas and refining high-sulfur crude oils. There are many sulfur recovery technologies available for different applications, however the most common conversion method used is the Claus process. Approximately 90 to 95 percent of recovered sulfur is produced by the Claus process.