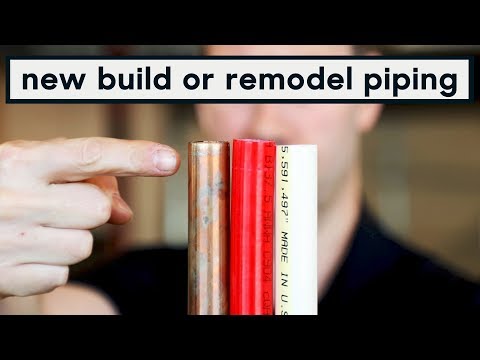

Copper pipes are probably the most traditional plumbing pipe used due to their extensive duration and reliability. They provide superior corrosion resistance, great material to be used for hot and cold water, and it can be managed easily.

Q. How do we determine the total discharge through parallel pipes?

Explanation: Total discharge in parallel pipes are determined by adding the discharges so developed in individual pipes. If Q1 is the discharge through pipe 1 and Q2 is the discharge through pipe 2. Then the total discharge through parallel pipes is equal to Q1+Q2.

Table of Contents

- Q. How do we determine the total discharge through parallel pipes?

- Q. Why head loss in the pipes that are in parallel the same?

- Q. What will happen when the pipes are connected in series and in parallel?

- Q. Why we adopt the parallel pipe system?

- Q. How is flow in parallel different than flow in series?

- Q. What will be loss of head when pipes are connected in series?

- Q. How do you calculate head loss in a pipe?

- Q. What is head loss equation?

- Q. Why is it called head loss?

- Q. Is head loss always positive?

- Q. How do you reduce head loss in a pipe?

- Q. How is head loss related to pressure loss?

- Q. Is Head Loss positive or negative?

- Q. What is the pressure head of a pump?

Q. Why head loss in the pipes that are in parallel the same?

RE: Head loss – Parallel pipes When in parallel, flows proportion through all components, such that the head loss between any common points are equal, thus flows change and head loss is equal.

Q. What will happen when the pipes are connected in series and in parallel?

In this arrangement the loss of head from section 1-1 to section 2-2 is equal to the loss of head in any one of the branch pipes. Similarly when a number of pipes be connected in parallel, then also, the total loss of head in the system is equal to the loss of head in any one of the pipes.

Q. Why we adopt the parallel pipe system?

Parallel pipeline is an important part of the solar heat exchanger, which uniformity of flow distribution directly affect solar heat collecting efficiency of the heating system. Many scholars at home and abroad have studied on the flow characteristics of parallel tubes.

Q. How is flow in parallel different than flow in series?

Figure 1: (a) Series systems – the flow rate through the entire system remains constant, the total head loss in this case is equal to the sum of the head losses in individual pipes, (b) parallel pipe system – head loss is the same in each pipe, and the total flow rate is the sum of the flow rates in individual pipes.

Q. What will be loss of head when pipes are connected in series?

Flow through pipe in series •When pipes of different diameters are connected end to end to form a pipe line, they are said to be in series. The total loss of energy (or head) will be the sum of the losses in each pipe plus local losses at connections.

Q. How do you calculate head loss in a pipe?

Determining the pipe diameter when the pipe length and flow rate are given for a specified pressure drop. hf = f L d v2 2g = 0,0225 500 0.2 6,42 2·9,81 = 117 m For inclined pipe the head loss is hf = ∆p ρg +z1 −z2 = ∆p ρg +Lsin10o. So pressure drop is ∆p = ρg(hf −500·sin 10o) = 900·9,81·(117−87) = 265·103.

Q. What is head loss equation?

From Wikipedia, the free encyclopedia. In fluid dynamics, the Darcy–Weisbach equation is an empirical equation, which relates the head loss, or pressure loss, due to friction along a given length of pipe to the average velocity of the fluid flow for an incompressible fluid.

Q. Why is it called head loss?

Pressure head is due to the static pressure, the internal molecular motion of a fluid that exerts a force on its container. Resistance head (or friction head or Head Loss) is due to the frictional forces acting against a fluid’s motion by the container.

Q. Is head loss always positive?

For example, friction, mixing, and heat transfer through a finite temperature difference all contribute to an irreversible loss of useful energy. (This is related to the second law of thermodynamics.) Thus, it turns out that the head loss term is always positive for any real flow, i.e.

Q. How do you reduce head loss in a pipe?

Solutions for Friction Loss

- Reduce interior surface roughness of the piping system.

- Increase pipe diameter of the piping system.

- Minimize length of piping system.

- Minimize the number of elbows, tees, valves, fittings, and other obstructions in the piping system; replace 90 degree turns with gentle bends.

Q. How is head loss related to pressure loss?

The head loss (or the pressure loss) represents the reduction in the total head or pressure (sum of elevation head, velocity head and pressure head) of the fluid as it flows through a hydraulic system. The total energy of the fluid conserves as a consequence of the law of conservation of energy.

Q. Is Head Loss positive or negative?

For control valves (and any other device in which head loss occurs across the device), head loss is positive and results in a pressure drop across the valve. If the network solution results in a pressure gain across the valve, then head loss will be negative.

Q. What is the pressure head of a pump?

Simply stated: a pump’s head is the maximum height that the pump can achieve pumping against gravity. Intuitively, if a pump can produce more pressure, it can pump water higher and produce a higher head.