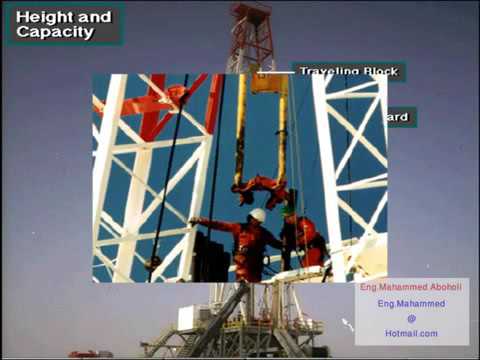

Q. What is the difference between Derrick and mast?

is that derrick is a device that is used for lifting and moving large objects while mast is a tall, slim post or tower, usually tapering upward, used to support, for example, the sails on a ship, flags, floodlights, or communications equipment such as an aerial, usually supported by guy-wires or mast can be the fruit …

Q. What is difference between lifting and rigging?

Rigging refers to the maneuvering of heavy objects by way of pushing, pulling, lifting or hoisting. Lifting is a way to move heavy objects by moving the object up from below most commonly using a jack.

Table of Contents

- Q. What is the difference between Derrick and mast?

- Q. What is difference between lifting and rigging?

- Q. What are the 4 lifting principles?

- Q. How much is rigging course?

- Q. What is a tandem lift?

- Q. Is tandem lifting safe?

- Q. What is considered a critical crane lift?

- Q. How do you plan a crane lift?

- Q. Does OSHA require a lift plan?

- Q. Who is responsible for a lifting plan?

- Q. What is the first step in planning a lift?

- Q. What four items should be included in a written rigging plan?

- Q. What should be included in a lift plan?

- Q. Is Loler mandatory?

- Q. What are the six stages of the safe lifting techniques?

- Q. Does a telehandler need a lift plan?

- Q. Can a telehandler be used to lift people?

- Q. Can you drive a telehandler on the road?

- Q. Is Puwer a legal requirement?

- Q. Who does Puwer cover?

- Q. What are the main requirements of Puwer?

- Q. Is a Risk Assessment a legal requirement?

- Q. What happens if risk assessments are not done?

- Q. Who carries out a risk assessment?

Q. What are the 4 lifting principles?

In order to get the maximum out of your training you need to apply the four key principles of training – specificity, progression, overload and individualisation – to what you do.

Q. How much is rigging course?

Basic rigging course cost is R5000 and takes 1 week. After the Rigger courses, a student attains a rigger certification.

Q. What is a tandem lift?

A tandem lift involving the simultaneous use of more than two cranes, hoists or other pieces of powered lifting equipment. if the load on any one crane, hoist or other piece of powered lifting equipment exceeds 75% of the rated capacity of that crane, hoist or other piece of powered lifting equipment.

Q. Is tandem lifting safe?

Tandem lifts can be very useful, and they are often used to place structural beams for bridges, move large loads, and lift long components from horizontal to vertical positions. However, tandem lifts have the potential to become very dangerous if not handled properly.

Q. What is considered a critical crane lift?

Critical lift means a lift that (1) exceeds 75 percent of the rated capacity of the crane or derrick, or (2) requires the use of more than one crane or derrick.

Q. How do you plan a crane lift?

Lift Planning – 8 Steps for Better Crane & Rigging Operations

- Weight of load.

- Location of the load’s center of gravity.

- Overall maximum dimensions of the load.

- Location and quantity of approved lifting lugs / lifting points.

Q. Does OSHA require a lift plan?

A Crane Lift Plan is required for every crane lift on a Dimeo project – see OSHA Subpart CC for definition of crane.

Q. Who is responsible for a lifting plan?

Lifting operations need to be properly planned by a competent person who has both practical and theoretical knowledge, and who has experience of planning lifts. The lifting plan needs to consider the risks involved, the equipment needed, the procedures for the lift, and who has to do what.

Q. What is the first step in planning a lift?

8 Steps to consider when drafting a lifting plan

- Weight of load.

- Location of the load’s center of gravity.

- Overall maximum dimensions of the load.

- Location and quantity of approved lifting lugs or lifting points.

- Selection of the appropriate rigging gear to suit lifting points.

- Height restriction.

- Risk Assessment.

Q. What four items should be included in a written rigging plan?

Rigging and Lifting Plan Components

- The rigging equipment.

- Shackles, turnbuckles, and slings being used.

- The weight being lifted.

- Center of gravity of the load being lifted.

- Crane capacity and crane charts.

- Height, width, and length of the lift.

- Atmospheric and environmental conditions when the process is being performed.

Q. What should be included in a lift plan?

The lift plan must include:

- The type, size, model, lifting capacity, certification date and serial number of the crane to be used.

- A list of items to be lifted/moved, including a description of each item’s weight, dimensions, center of gravity, and presence of hazardous toxic materials.

Q. Is Loler mandatory?

LOLER Inspections These are a legal requirement and should be carried out by a competent person.

Q. What are the six stages of the safe lifting techniques?

Page 1

- Identify the object, plan ahead • Where do you need to take the load? •

- 2 Holding. the object • Make a decision on how and where to hold the object.

- 3 Posture. •

- 4 Lifting. •

- 5 Walking. with a load • Keep the load as close to your body as possible with your arms straight.

- 6 Unloading. •

Q. Does a telehandler need a lift plan?

All work involving telehandlers must be planned by a competent person, appropriately supervised and carried out in a safe manner. Where a telehandler is to be used as a crane for lifting suspended loads, additional planning is required by a competent person.

Q. Can a telehandler be used to lift people?

Basic telehandler operator training does not include the lifting of suspended loads, the lifting of persons or the use of other attachments. If such tasks are to be carried out the employer must ensure that the operator is suitably trained and assessed as competent.

Q. Can you drive a telehandler on the road?

What do I need to drive a telehandler on the road? The vehicle must be registered and licensed. But this will limit its use on the road to agricultural activity. So this is fine if you are using it for bale-carting, transporting fertiliser, or travelling to a grain store to load a lorry.

Q. Is Puwer a legal requirement?

While the guidance provided in the PUWER Approved Code of Practice and Guidance (PUWER ACOP) is not law, it has special status under the Health and Safety at Work Act.

Q. Who does Puwer cover?

PUWER (the Provision and Use of Work Equipment Regulations) covers any equipment that’s used in a workplace and could pose a risk to people’s health and safety. It applies to both portable and stationery equipment, from handheld power tools to air-conditioning units and computers.

Q. What are the main requirements of Puwer?

PUWER requires that equipment provided for use at work is:

- suitable for the intended use.

- safe for use, maintained in a safe condition and inspected to ensure it is correctly installed and does not subsequently deteriorate.

- used only by people who have received adequate information, instruction and training.

Q. Is a Risk Assessment a legal requirement?

So, risk assessments are a legal requirement for every employer and self-employed person, and they must assess the risks not only to those they employ, but also the risks to anyone else who may be affected by the work activities.

Q. What happens if risk assessments are not done?

Businesses have a responsibility to ensure all staff are aware of and understand the risks associated with their work as well as the environment they work in. A failure to do this can result in large fines and opens up the possibility of accidents in the work place.

Q. Who carries out a risk assessment?

employer