Q. What is the difference between yield stress and yield point?

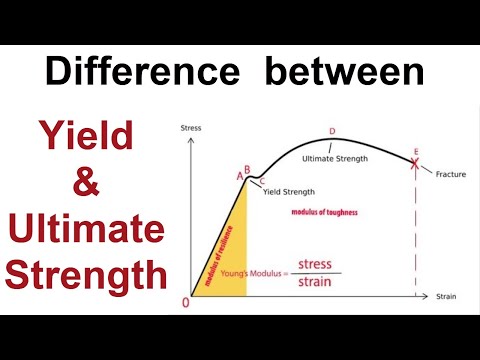

Yield strength or yield stress is the material property defined as the stress at which a material begins to deform plastically whereas yield point is the point where nonlinear (elastic + plastic) deformation begins. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible.

Q. What is yielding point and breaking point?

In materials science and engineering, the yield point is the point on a stress-strain curve that indicates the limit of elastic behavior and the beginning of plastic behavior. Below the yield point, a material will deform elastically and will return to its original shape when the applied stress is removed.

Table of Contents

- Q. What is the difference between yield stress and yield point?

- Q. What is yielding point and breaking point?

- Q. What is rupture point?

- Q. What does yield point mean?

- Q. What happens at yield point?

- Q. How do you calculate 0.2 yield strength?

- Q. What is the 0.2 offset yield strength?

- Q. How do you calculate 0.2 Yield stress?

- Q. What is yield stress formula?

- Q. What is ultimate stress formula?

- Q. How is yield calculated?

- Q. What is the unit of yield strength?

- Q. What is yield strength of steel?

- Q. What is yield point in drilling mud?

- Q. What is the value of Young’s modulus of steel?

- Q. What does a higher Young’s modulus mean?

- Q. What does Young’s modulus measure?

- Q. What does a lower Young’s modulus mean?

- Q. How do you use Young’s modulus?

- Q. Is Young’s modulus affected by temperature?

- Q. Why does the Young’s modulus decrease with temperature?

- Q. Which material has least Young’s modulus?

- Q. How does Young’s modulus change with rise in temperature?

Q. What is rupture point?

Rupture point: a point on the stress-strain or force-deformation curve at which the axially loaded specimen ruptures under a load. In biological materials, rupture may cause puncture of shell or skin, cracking or fracture planes.

Q. What does yield point mean?

The yield point is defined as the stress beyond which a material deforms by a relatively large amount for a small increase in the stretching force.

Q. What happens at yield point?

The yield point, alternatively called the elastic limit, marks the end of elastic behaviour and the beginning of plastic behaviour. When stresses less than the yield point are removed, the material returns to its original shape.

Q. How do you calculate 0.2 yield strength?

The yield strength is typically defined by the “0.2% offset strain”. The yield strength at 0.2% offset is determined by finding the intersection of the stress-strain curve with a line parallel to the initial slope of the curve and which intercepts the abscissa at 0.2%.

Q. What is the 0.2 offset yield strength?

The 0.2% offset yield strength (0.2% OYS, 0.2% proof stress, RP0. 2, RP0,2) is defined as the amount of stress that will result in a plastic strain of 0.2%. This is illustrated by the blue line in Figure 1 below. This is the yield strength that is most often quoted by material suppliers and used by design engineers.

Q. How do you calculate 0.2 Yield stress?

The yield strength at 0.2% offset, for example, is obtained by drawing through the point of the horizontal axis of abscissa ε = 0.2% (or ε = 0.002), a line parallel to the initial straight-line portion of the stress-strain diagram.

Q. What is yield stress formula?

The most common engineering approximation for yield stress is the 0.2 percent offset rule. To apply this rule, assume that yield strain is 0.2 percent, and multiply by Young’s Modulus for your material: σ = 0.002 × E /sigma = 0.002/times E σ=0.

Q. What is ultimate stress formula?

It is equivalent to the maximum load that can be carried by one square inch of cross-sectional area when the load is applied as simple tension. You can use the below given ultimate stress formula to calculate the UTS on any material. UTS = Pmax / Ao.

Q. How is yield calculated?

The yield on cost can be calculated by dividing the annual dividend paid and dividing it by the purchase price. The difference between the yield on cost and the current yield is that, rather than dividing the dividend by the purchase price, the dividend is divided by the stock’s current price.

Q. What is the unit of yield strength?

N.m-2

Q. What is yield strength of steel?

Yield Strength in Steel Yield strength is the maximum stress that can be applied before it begins to change shape permanently. This is an approximation of the elastic limit of the steel. If stress is added to the metal but does not reach the yield point, it will return to its original shape after the stress is removed.

Q. What is yield point in drilling mud?

Yield Point (YP) is resistance of initial flow of fluid or the stress required in order to move the fluid. It can be simply stated that the Yield Point (YP) is the attractive force among colloidal particles in drilling fluid.

Q. What is the value of Young’s modulus of steel?

| Material | Tensile Modulus (Young’s Modulus, Modulus of Elasticity) – E – (GPa) | Ultimate Tensile Strength – σu – (MPa) |

|---|---|---|

| Steel, stainless AISI 302 | 180 | 860 |

| Steel, Structural ASTM-A36 | 200 | 400 |

| Tantalum | 186 | |

| Thorium | 59 |

Q. What does a higher Young’s modulus mean?

The higher the modulus, the more stress is needed to create the same amount of strain; an idealized rigid body would have an infinite Young’s modulus. Conversely, a very soft material such as a fluid, would deform without force, and would have zero Young’s modulus.

Q. What does Young’s modulus measure?

The Young’s modulus (E) is a property of the material that tells us how easily it can stretch and deform and is defined as the ratio of tensile stress (σ) to tensile strain (ε).

Q. What does a lower Young’s modulus mean?

elastic

Q. How do you use Young’s modulus?

Young’s modulus equation is E = tensile stress/tensile strain = (FL) / (A * change in L), where F is the applied force, L is the initial length, A is the square area, and E is Young’s modulus in Pascals (Pa). Using a graph, you can determine whether a material shows elasticity.

Q. Is Young’s modulus affected by temperature?

When the temperature increases, the atomic thermal vibrations increase, and this will cause the changes of lattice potential energy and curvature of the potential energy curve, so the Young’s modulus will also change.

Q. Why does the Young’s modulus decrease with temperature?

The Effect of Temperature on Young’sModulus. When the temperature increases, the atomic thermal vibrations increase, and this will cause the changes of lattice potential energy and curvature of the potential energy curve, so the Young’s modulus will also change.

Q. Which material has least Young’s modulus?

A flexible material has a low Young’s modulus and changes its shape considerably (e.g. rubbers). A stiff material requires high loads to elastically deform it – not to be confused with a strong material, which requires high loads to permanently deform (or break) it.

Q. How does Young’s modulus change with rise in temperature?

Note:The Young’s modulus is a measure of stiffness of the material. With rise in temperature, the length of the material increases which decreases its stiffness. Thus, we can say that with rise in the temperature, the Young’s modulus decreases.