Q. What is web offset ink?

Web offset is a form of offset printing in which a continuous roll of paper is fed through the printing press. Pages are separated and cut to size after they have been printed. Web offset printing is used for high-volume publications such as mass-market books, magazines, newspapers, catalogs and brochures.

Q. What type of ink is used in offset printing?

PIGMENT: There are two basic types of pigment used in offset printing inks. Organic pigment, which is made from carbon, is used for making black ink. Inorganic pigments, which are made by mixing various chemicals together, are used for colored inks.

Table of Contents

- Q. What is web offset ink?

- Q. What type of ink is used in offset printing?

- Q. What is offset ink made of?

- Q. What are advantages of offset web printing?

- Q. Is offset printing the same as lithography?

- Q. What are the 4 basic ink types?

- Q. What is the viscosity of offset ink?

- Q. Is Offset Printing water based?

- Q. What is the difference between offset printing and flexographic printing?

- Q. Is offset printing dying?

- Q. What is standard printer ink made of?

- Q. What is offset press?

Q. What is offset ink made of?

VEHICLE: Vehicle is the liquid that holds the particles of pigment and carries them to the paper. There are two kinds of vehicles used in offset inks: oils such as soya oil or lin- seed oil (which is a yellowish oil made from flax); and synthetic vehicles, which are liquids resulting from the mixture of chemicals.

Q. What are advantages of offset web printing?

What are the Advantages of Offset Printing:

- Large quantities can be printed cost effectively.

- The more you print, the cheaper the price per piece.

- A large variety of paper types with custom finishes can be used.

- Special custom inks such as metallic and Pantone colors are available.

Q. Is offset printing the same as lithography?

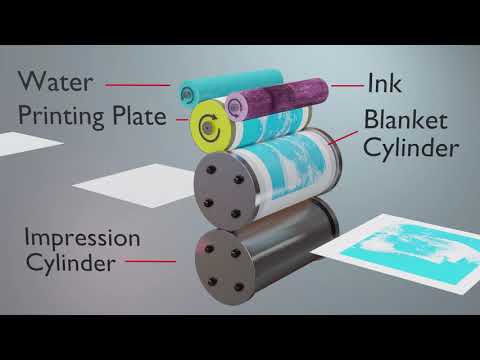

Offset printing, also called offset lithography, is a method of mass-production printing in which the images on metal plates are transferred (offset) to rubber blankets or rollers and then to the print media. The print media, usually paper, does not come into direct contact with the metal plates.

Q. What are the 4 basic ink types?

Printer Ink Most color printers follow the CMYK (cyan, magenta, yellow, black) model. To make new colors and create an image, the printers will layer tiny dots of the four printer colors.

Q. What is the viscosity of offset ink?

The zero shear viscosity should be in the range of 200 ∼ 500 Pa. s and the infinite viscosity greater than 0.5 Pa. s. The viscosity of ink varies with shear and temperature.

Q. Is Offset Printing water based?

When used in combination with the lithographic process, which is based on the repulsion of oil and water, the offset technique employs a flat (planographic) image carrier. Ink rollers transfer ink to the image areas of the image carrier, while a water roller applies a water-based film to the non-image areas.

Q. What is the difference between offset printing and flexographic printing?

Offset printing machines can print on materials such as; paper, metal, cardboard, cellophane and vinyl. The main difference with both processes is that offset printing is only done on flat surface while Flexographic printing can be used on almost any substrate with a flexible surface.

Q. Is offset printing dying?

Offset Printing. Once considered to be a dying brand of printing, offset printing has seen a revitalization. Used for printing envelopes, pocket folders, carbon business forms and many other mediums; from one color to four, offset printing is alive and more vibrant than ever.

Q. What is standard printer ink made of?

Standard rollerball ink is made from particles of carbon black, a pigment substance. These particles are segregated from each other by a polymer that is adsorbed onto the surface of the carbon black particles. Finally, a solvent is applied so that the ink will flow.

Q. What is offset press?

Definition of: offset press. offset press. A printer that uses an intermediate rubber-coated cylinder known as a “blanket” to transfer the image onto the paper. Instead of transferring the image from a metallic drum onto paper as is done with most digital printers, the image is “offset” onto the blanket and then to paper.