Q. Which surface does the dropwise condensation occurs on?

Dropwise condensation of steam has been observed on chromium and gold surfaces which are very smooth, without use of a promoting agent.

Q. Why is there condensation in dropwise?

Under certain conditions, dropwise condensation provides for much higher heat transfer rates than filmwise condensation. Although a drop has a larger surface area than a film occupying the same surface area, this difference is relatively small.

Table of Contents

- Q. Which surface does the dropwise condensation occurs on?

- Q. Why is there condensation in dropwise?

- Q. How do you promote dropwise condensation?

- Q. What is the difference between Filmwise and dropwise condensation?

- Q. What is the reason for the high convective heat transfer coefficient in dropwise condensation?

- Q. What is film condensation process?

- Q. Is dropwise condensation stable?

- Q. Why is heat transfer more in dropwise condensation?

- Q. How do you promote condensation?

- Q. Why is film wise and dropwise condensation?

- Q. How does dropwise condensation differ from film condensation which mode of condensation is characterized by larger heat transfer rates?

- Q. How can the rate of heat transfer from dropwise condensation?

- Q. What do you need to know about Dropwise condensation?

- Q. How are silicon promoters used in Dropwise condensation?

- Q. When do dropwise surfaces degrade, film condensation occurs?

- Q. What is the ratio of Dropwise condensation of steam?

Q. How do you promote dropwise condensation?

Dropwise condensation is achieved by adding a promoter chemical into the vapor, and/or roughened surfaces and surface and surface coated with hydrophobic impurities like fatty acids and organic compounds, known as dropwise promoters.

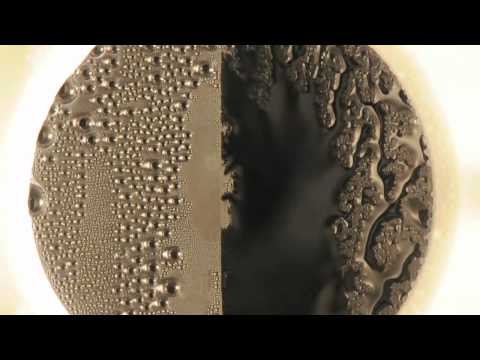

Q. What is the difference between Filmwise and dropwise condensation?

In filmwise condensation a laminar film of vapour is created upon a surface. This film can then flow downwards, increasing in thickness as additional vapour is picked up along the way . In dropwise con- densation vapour droplets form at an acute angle to a surface .

Q. What is the reason for the high convective heat transfer coefficient in dropwise condensation?

Explanation: The convective coefficient for condensation should be high because condensation refers to a change from the vapor to a liquid phase. Explanation: It generally occurs on oily surface. It is the convective heat transfer process that is associated with a change in the phase of a fluid.

Q. What is film condensation process?

In film condensation, the condensate wets the surface and forms a liquid film on the surface that slides down under the influence of gravity. The film increases a thermal resistance to heat flow between the surface and the vapour. The rate of heat transfer is reduced because of this resistance.

Q. Is dropwise condensation stable?

The heat transfer coefficient was found to increase with increasing steam pressure and decrease with increasing surface subcooling. The stability of dropwise condensation was maintained for 8 months. The measured condensation heat transfer coefficient was found to be 5.5 times larger than that for film condensation.

Q. Why is heat transfer more in dropwise condensation?

Dropwise condensation occurs when a vapor condenses on a surface not wetted by the condensate. For nonmetal vapors, dropwise condensation gives much higher heat transfer coefficients than those found with film condensation. Nonwetting agents, known as dropwise promoters, are needed to promote dropwise condensation.

Q. How do you promote condensation?

When gas molecules transfer their energy to something cooler, they slow down and their attractions cause them to bond to become a liquid. Making water vapor colder increases the rate of condensation. Increasing the concentration of water vapor in the air increases the rate of condensation.

Q. Why is film wise and dropwise condensation?

In film wise condensation, the surface over which the steam condenses is wet-able and hence, as the steam condenses, a film of condensate is formed. Generally, film wise condensation results in low heat transfer rates as the film of condensate impedes the heat transfer.

Q. How does dropwise condensation differ from film condensation which mode of condensation is characterized by larger heat transfer rates?

The drops form cracks, pits, and cavities on the surface and may grow and coalesce through continued condensation. Which mode of condensation is characterized by larger heat transfer rates? Dropwise condensation heat transfer rates are more than an order of magnitude larger than those associated with film condensation.

Q. How can the rate of heat transfer from dropwise condensation?

During the condensation process, a continuous liquid film flowing downward will be formed and the steam must pass through this film to exchange heat of the surface. It will increase the thermal resistance of heat transfer, and thus the heat transfer capability is limited.

Q. What do you need to know about Dropwise condensation?

Dropwise condensation is achieved by adding a promoter chemical into the vapor, and/or roughened surfaces and surface and surface coated with hydrophobic impurities like fatty acids and organic compounds, known as dropwise promoters.

Q. How are silicon promoters used in Dropwise condensation?

Dropwise condensation is provoked artificially with the help of silicons, teflon, assortment of waxes, and fatty acids. These promoters are used to promote dropwise condensation but most promoters are highly unstable and lose their effectiveness with time due to oxidation, fouling and removal of the promoter from the surface.

Q. When do dropwise surfaces degrade, film condensation occurs?

When dropwise surfaces degrade, they convert to filmwise condensation. So most condensers are designed on the assumption that film condensation will take place on the surface eventually. Dropwise condensation is useful in powerplant heat exchangers, thermal desalination, self-cleaning surfaces, and heating and air conditioning.

Q. What is the ratio of Dropwise condensation of steam?

The diameter ratio between the largest and smallest drops during dropwise condensation of steam is around 10 6 . Le Fevre and Rose (1966) have noted that three factors are involved in the mechanism of heat transfer through a single drop.