Q. Why is it important to use a small amount of bacteria when preparing a smear?

Just as in preparing a smear, you only need a small amount of organism. If you have too many organisms, you won’t be able to see the morphology of individual cells. It is also important not use too much nigrosin. If it is too thick, the background will have a cracked appearance similar to mud puddles drying in the sun.

Q. Why is water added to the slide when making a smear from solid media?

If your inoculum is growing on a slant or plate, you must first add a loopful of water before makeing your smear Why? to dilute the sample and to make it easier to spread the cells into a thin smear.

Table of Contents

- Q. Why is it important to use a small amount of bacteria when preparing a smear?

- Q. Why is water added to the slide when making a smear from solid media?

- Q. What are some precautions that should be taken during the Gram staining technique?

- Q. What is the safest way of drying bacterial smear?

- Q. How can you achieve a good bacterial smear?

- Q. What is the disadvantage of preparing thick smears for bacterial smears?

- Q. What happens if a smear is too thick?

- Q. Why is thick blood film not fixed?

- Q. Why are both thin and thick smears prepared?

- Q. Does thick blood make you tired?

- Q. What is difference between thin and thick film?

- Q. What are the characteristics of a good thin film?

- Q. What are the methods used to deposit thin films?

- Q. What are the applications of thin films?

- Q. How thin are thin films?

- Q. What is the minimum range of thin film?

- Q. Which is the aim of thin film deposition?

- Q. Which deposition process grows the thin film rather than deposit it?

- Q. What is ALD technique?

- Q. What is deposition technology used for?

- Q. What do you think is the most important thing that is manufactured using deposition?

- Q. What are the different types of sputtering?

- Q. How does a sputtering machine work?

- Q. Why is sputtering used?

Q. What are some precautions that should be taken during the Gram staining technique?

Safety Precautions Gram stain materials will stain skin and other materials. Care should be taken when sterilizing the inoculating loop and when flame- fixing slides. Wear chemical splash goggles and chemical-resistant gloves. Wash hands thoroughly with soap and water before leaving the laboratory.

Q. What is the safest way of drying bacterial smear?

In order to heat fix a bacterial smear, it is necessary to first let the bacterial sample air dry. Then either place the slide in the slide holder of a microincinerator, or pass the dried slide through the flame of a Bunsen burner 3 or 4 times, smear side facing up.

Q. How can you achieve a good bacterial smear?

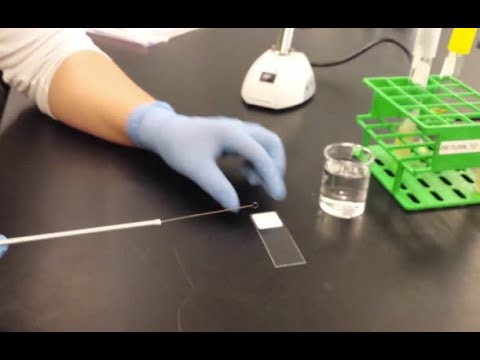

SMEAR PREPARATION

- Place one needle of solid bacterial growth or two loops. of liquid bacterial growth in the center of a clean slide.

- If working from a solid medium, add one drop (and only one drop)

- Now, with your inoculating loop, mix the specimen with the water.

- Place the slide on a slide warmer and wait for it to dry.

Q. What is the disadvantage of preparing thick smears for bacterial smears?

Once this is done, the staining procedure begins. Do NOT make your smear suspensions too thick. The dye will not penetrate well, and there will be far too many bacterial cells to see individual shapes and arrangements.

Q. What happens if a smear is too thick?

If the smear is too thick, proper decolorizing will not be possible. If the smear is overheated during heat fixing, the cell walls will rupture. Cells from old cultures may stain Gram negative even if the bacteria are Gram positive.

Q. Why is thick blood film not fixed?

Thick films should not be fixed with methanol (or direct heat). During the aqueous staining procedure the unfixed RBC lyse, leaving the remains of WBC and any malaria parasites present behind. If thick films are fixed before staining they will be too dense to examine.

Q. Why are both thin and thick smears prepared?

Blood smears are taken most often from a finger prick. Thick and thin blood smears will let doctors know the percentage of red blood cells that are infected (parasite density) and what type of parasites are present. A thick blood smear is a drop of blood on a glass slide.

Q. Does thick blood make you tired?

Thick blood can lead to strokes or tissue and organ damage. Symptoms include lack of energy (fatigue) or weakness, headaches, dizziness, shortness of breath, visual disturbances, nose bleeds, bleeding gums, heavy menstrual periods, and bruising.

Q. What is difference between thin and thick film?

Thin film has a thickness in the order of 0.1 micrometer or smaller, while thick film is around thousands time thicker. However, the main difference is method the resistive film is applied onto the substrate. Thin film resistors have a metallic film that is vacuum deposited on an insulating substrate.

Q. What are the characteristics of a good thin film?

Features of thin film

- Uniformity between neighboring elements.

- Minimal defects > Low noise.

- Temperature stability, high precision.

Q. What are the methods used to deposit thin films?

In order to obtain thin films with good quality, there are two common deposition techniques: physical and chemical depositions. It can be summarized as shown in Table 1. Vacuum thermal evaporation….Chemical vapor deposition (CVD)

- Low pressure (LPCVD)

- Plasma enhanced (PECVD)

- Atomic layer deposition (ALD)

Q. What are the applications of thin films?

Thin film materials have been used in semiconductor devices, wireless communications, telecommunications, integrated circuits, rectifiers, transistors, solar cells, light- emitting diodes, photoconductors and light crystal displays, lithography, micro- electromechanical systems (MEMS) and multifunctional emerging …

Q. How thin are thin films?

Generally speaking a thin film has a thickness of less than 1 μm, and is deposited on the surface of a substrate by one of several distinct deposition methods [28.2].

Q. What is the minimum range of thin film?

What is the minimum thickness of thin film required for constructive interference in the reflected light through it ? (Given, the refractive index of the film =1.5, wavelength of the lilght incident on the film =600 nm.

Q. Which is the aim of thin film deposition?

Thin film deposition is the process of creating and depositing thin film coatings onto a substrate material. These coatings can be made of many different materials, from metals to oxides to compounds.

Q. Which deposition process grows the thin film rather than deposit it?

Heteroepitaxy refers to the case in which the film being deposited is different than the substrate. Techniques used for epitaxial growth of thin films include molecular beam epitaxy, chemical vapor deposition, and pulsed laser deposition.

Q. What is ALD technique?

Atomic layer deposition (ALD) is a vapor phase technique used to deposit thin films onto a substrate. The process of ALD involves the surface of a substrate being exposed to alternating precursors, which do not overlap but instead are introduced sequentially.

Q. What is deposition technology used for?

Thin film deposition is the act of applying a thin film on the surface of another material. It is used in the manufacturing of devices such as computers and thin film transistors. It also finds applications in the production of semiconductors as well as in simple everyday objects as a typical household mirror.

Q. What do you think is the most important thing that is manufactured using deposition?

Titanium dioxide (TiO2) is probably the most important and widely used thin film optical material and is also used in photocatalytic devices and self-cleaning windows, and may have important applications in hydrogen production.

Q. What are the different types of sputtering?

The main types of Sputtering are discussed below:

- DC diode sputtering. With a DC voltage = 500 – 1000 V, an argon low-pressure plasma is ignited between a target and a substrate.

- RF sputtering.

- DC Triode Sputtering.

- Magnetron.

- Reactive sputtering.

Q. How does a sputtering machine work?

Magnetron sputtering deposition uses magnets behind the negative cathode to trap electrons over the negatively charged target material so they are not free to bombard the substrate, allowing for faster deposition rates. The most common magnetron sputter cathode/target shapes are circular and rectangular.

Q. Why is sputtering used?

One of the earliest widespread commercial applications of sputter deposition, which is still one of its most important applications, is in the production of computer hard disks. Because of the low substrate temperatures used, sputtering is an ideal method to deposit contact metals for thin-film transistors.