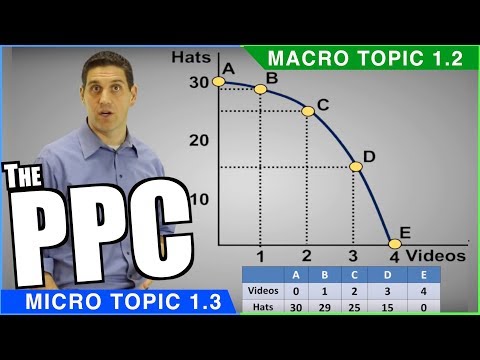

The production possibilities curve (PPC) is a graph that shows all of the different combinations of output that can be produced given current resources and technology. Sometimes called the production possibilities frontier (PPF), the PPC illustrates scarcity and tradeoffs.

Q. What is the line on a production possibilities curve called?

The line on a production possibilities curve showing the relative amounts of two types of goods produced using all resources is called the. production possibilities frontier.

Table of Contents

- Q. What is the line on a production possibilities curve called?

- Q. What is PPC draw the diagram?

- Q. How many types of production are there?

- Q. What are methods of production?

- Q. What are the 4 M’s of marketing?

- Q. What is 5M method?

- Q. How important is 4Ms?

- Q. Do you believe that 4Ms is effective in production?

- Q. What are the positive effects of applying 4Ms of operation?

- Q. How do you do a 4M analysis?

- Q. How important is 4Ms in business operations Brainly?

- Q. What is considered as the most significant factor of production Brainly?

- Q. What are 6 M’s?

- Q. What are the 5-M’s of operations?

- Q. What are the five elements of the 5M model?

- Q. What are the 7 M’s of management?

Q. What is PPC draw the diagram?

(also called a production possibilities frontier) a graphical model that represents all of the different combinations of two goods that can be produced; the PPC captures scarcity of resources and opportunity costs.

Q. How many types of production are there?

Four types of production. There are 4 different types of productions which are most commonly used. Which type of production should be used by the company depends on the type of product being manufactured, the demand of the product as well as the supply of raw materials.

Q. What are methods of production?

The main methods of production are: job production. batch production. flow production.

Q. What are the 4 M’s of marketing?

The 4 M’s are: make, manage, monitor, and measure. These principles are especially relevant for social media and influencer marketing, which are crucial for succeeding today. Make – This doesn’t refer to making products (even if that’s part of what you do) but connecting brand influencers and potential customers.

Q. What is 5M method?

The 5M model is a troubleshooting and risk-management model used for aviation safety. Based on T.P. Management (leadership): the prevailing supervisory approach in terms of regulations, policies, procedures, and attitude involved in establishing, operating, maintaining, and decommissioning.

Q. How important is 4Ms?

4Ms represents the most important factors which influence on the final result of any concerned process. For a long time using the 4Ms method, not only for root cause analysis (cause-and-effect) but also for many purposes, I modify a little bit on this method and connect it to the IPO (Input – Process – Output) model.

Q. Do you believe that 4Ms is effective in production?

Answer: Absolutely, the 4Ms technique is able to apply in any phase of a process from the concept to design phase, from prototype to mass production, from daily control to continuous improvement, innovation, etc.,.

Q. What are the positive effects of applying 4Ms of operation?

Planned Maintenance: The 4M framework is instrumental in reducing breakdowns by restoring the equipment, correcting basic weaknesses, and preventing issues from coming back. Working together, 4Ms helps the pillars to understand where the weaknesses are and address them through restoration and prevention.

Q. How do you do a 4M analysis?

4M Analysis Resolution of Issues

- Select Condition from list of Issues on the fishbone. Example: “Design – Visual access limited”

- Select Proper Problem Solving Methodology. Problem Solving Methodologies. Autonomous Maintenance Process. Standards. Inspection, Cleaning & Lubrication. Root Cause Analysis. Cap Do Process.

Q. How important is 4Ms in business operations Brainly?

Answer: Exploring these 4Ms provides us with a structured framework for root cause analysis by helping us to understand how each one may have contributed to a particular issue. Safety: The 4Ms play their part in identifying root causes and improvement opportunities within the safety sub-committees.

Q. What is considered as the most significant factor of production Brainly?

Answer: Human capital is the most important factor of production because it puts together land, labour and physical Capital and produce an output either to use for self consumption or to sell in the market.

Q. What are 6 M’s?

6Ms of Production (man, machine, material, method, mother nature and measurement) The 6Ms of production – Manpower, Method, Machine, Material, Milieu and Measurement – is a mnemonic representing the characteristic dimensions to consider when brainstorming during “cause and effect” problem-solving sessions.

Q. What are the 5-M’s of operations?

Production management’s responsibilities are summarized by the “five M’s”: men, machines, methods, materials, and money.

Q. What are the five elements of the 5M model?

The five elements need to be considered as assets which the organisation has committed to its current marketing strategy and they include Manpower (Staffing), Materials (Production), Machinery (Equipment), Minutes (Time) and Money (Finances). The model itself can be used in a number of different ways.

Q. What are the 7 M’s of management?

The 7M’s to Management covers Man (HR), Material (basic ingredient in management), Machines (basic tools), Money, Method (the art of doing), Management (functions of management) and Moral Values (the way business is conducted).